UL FM Approved Fire Pumps: Features, Standards, and Uses

January 14, 2026UL FM approved fire pumps are essential for ensuring the safety of facilities and protecting them from fire hazards, as they provide high-quality performance in accordance with global safety standards approved by UL (Underwriters Laboratories) and FM (Factory Mutual).

These pumps are designed to withstand harsh conditions and provide optimal water flow in emergencies, ensuring effective protection of buildings and property.

In this article, we will discuss the importance of UL FM approved fire pumps and how to choose the most suitable system for your needs, highlighting United Company for Electromechanical Projects, the exclusive agent in Egypt for Watex Emirates.Ratia.

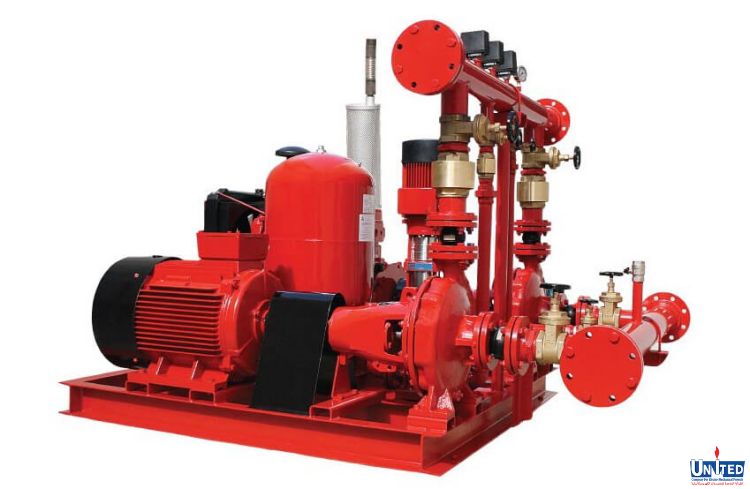

UL FM fire pumps

UL and FM certified fire pumps are pumps specifically designed for use in fire fighting systems and are distinguished by having obtained two important global certifications: UL (Underwriters Laboratories) and FM (Factory Mutual).

These international standards ensure that the pumps meet the highest levels of quality, efficiency, and safety. These pumps are used in buildings and industrial and commercial facilities where fire suppression systems must be ready for immediate use in emergencies.

UL FM pumps come in a variety of sizes and designs to meet the needs of different systems, whether for horizontal or vertical pumping. They are designed to operate efficiently in the harshest environmental conditions, such as high temperatures or high pressure, making them the top choice for building owners and fire protection system designers.

UL FM approved fire pumps can be relied upon thanks to their UL and FM certification, ensuring efficient and sustainable performance for as long as possible, reducing the likelihood of breakdowns and increasing the level of protection and safety.

Read more: fire fighting pump price

UL fire pumps

UL-approved fire pumps are an essential part of fire-fighting systems in large and small facilities, as they are highly capable of pumping water efficiently and quickly in emergencies.

These pumps are manufactured to Underwriters Laboratories (UL) standards, which ensure the highest levels of quality and performance. UL pumps have undergone rigorous testing to verify their durability and ability to operate under high pressure and harsh conditions, making them the ideal choice for providing reliable fire protection.

Using UL pumps in fire suppression systems contributes to enhanced safety and rapid emergency response, reducing potential damage and preserving lives and property.

What is the difference between UL and non-UL pumps?

The difference between UL-certified and non-UL-certified pumps lies in several aspects related to quality, performance, and compliance with safety standards. Here are the key differences regarding UL-certified fire pumps:

- Standards and Accreditation

- UL pumps:They are manufactured to the standards of Underwriters Laboratories (UL), an international organization that sets rigorous standards for testing and certifying safety-related products. These standards require high performance, durability, and emergency safety.

- Non-UL pumps:It may not be subject to the same rigorous testing mandated by UL, and therefore may not have the same level of accreditation with regard to safety and quality.

- Performance tests

- UL pumps:It undergoes rigorous testing including pressure resistance, ability to pump large quantities of water, operation under harsh conditions such as high temperatures, and other endurance and reliability tests.

- Non-UL pumps:They may not undergo these rigorous tests, which means they may not be as reliable in emergency situations.

- Efficiency and reliability

- UL pumps: The difference between UL and FM fire pumps is that UL pumps are known for their high level of efficiency and reliability in systems that require an immediate and accurate response, such as fire suppression systems.

- Non-UL pumps: Their efficiency and reliability may not be guaranteed, and they may experience problems during operation under difficult conditions.

- Cost

- UL pumps: They are usually more expensive as a result of compliance with strict quality standards and the multiple tests they undergo.

- Non-UL pumps: These are often less expensive, but may carry a higher risk of not being able to perform as required in emergency situations.

- Confidence in the market

- UL pumps: Widely used in large industrial buildings and facilities that require the highest levels of safety and protection, they are preferred by engineers and contractors because of their reliability.

- Non-UL pumps: These may be less well-known or used in installations that do not require strict levels of protection.

In short, UL pumps guarantee a higher level of safety and quality, while non-UL pumps may not provide the same level of reliability in critical conditions.

What does non-ul mean for an air pump?

It is a synthetic or chemical gas used in fire suppression. It works by extinguishing the fire by removing free radicals or reducing the heat element, and is used to fight fires of various sizes.

This gas is available in multiple specifications, including UL and non-UL certifications, as well as compliance with national, Chinese, and European standards. These systems come complete with operating devices, including electrical and manual panels, discharge hoses, alarms, and sprayers. The use of these systems is mandatory in electrical and pump rooms to ensure effective protection.

Learn more about: How to use: fire extinguishers

What is an ABC fire extinguisher?

ABC fire extinguishers are versatile and widely used devices for fire protection in buildings. They are designed to extinguish Class A (wood, paper, fabric), Class B (flammable liquids), and Class C (electrical fires) fires. These extinguishers contain a dry chemical powder effective against various types of fires.

Commonly used in homes, offices, and commercial buildings, these fire extinguishers are easy to operate and often come equipped with a hose and pressure gauge to ensure rapid and accurate powder dispersal. ABC fire extinguishers provide a vital first line of defense against fires, enabling a swift response to emergencies and giving the user peace of mind.

To ensure that fire extinguishers are ready at any time, regular inspection and maintenance are essential to maintain their efficiency and effectiveness when needed.

What is the difference between a CO2 and an ABC fire extinguisher?

|

Comparison point |

Carbon dioxide (CO₂) fire extinguisher |

Dry chemical powder (ABC) fire extinguisher |

|

Material used |

pressurized carbon dioxide gas |

Dry chemical powder (often ammonium phosphate) |

|

Fire extinguishing mechanism |

Smother the fire by reducing oxygen and cooling the burning material. |

Isolating the burning material with an insulating layer + stopping the chemical reaction |

|

Suitable for fires |

Category B: Flammable liquids (gasoline, oils), electricity: electronic devices and boards |

Category A: Solids (wood, paper), Category B: Liquids, Category C: Flammable gases |

|

Key Features |

Completely clean, leaves no residue, ideal for laboratories and technical offices. |

Comprehensive and covers most types of domestic and industrial fires in one device |

|

Disadvantages |

Ineffective against solids, disperses quickly in open spaces |

It leaves behind a powder that may damage sensitive devices and requires thorough cleaning. |

|

Impact on equipment |

Very safe for sensitive equipment and computers |

Powder residue may cause corrosion or damage to electrical circuits |

Summary and explanation:

- Use CO₂: In server rooms, laboratories, or anywhere that contains expensive electronic equipment and you want to extinguish a fire without damaging the equipment.

- Use ABC: as a comprehensive option for homes, warehouses, and workshops, where fire sources vary between wood, liquids, and gases.

How to inspect fire pumps

Inspecting UL/FM fire pumps is vital to ensuring their readiness for emergency use. The inspection is conducted according to specific standards to guarantee their efficiency and safety. Here are the steps for inspecting fire pumps:

- Visual examination

- Check the overall condition of the pump and make sure there are no leaks or damage to the external parts.

- Check the pipelines and valves to ensure they are in good condition.

- Make sure the tanks are full of water and there are no blockages in the supply lines.

- Startup test

- Manually operate the pump to check the motor's operating efficiency and response speed.

- Make sure the pump starts correctly, whether automatically or manually.

- flow pressure measurement

- Measure the flow pressure produced by the pump using appropriate measuring devices to ensure that the pump is able to provide the pressure required for fire fighting.

- Comparing the pressure results with the specified standards for the fire suppression system.

- Valve inspection

- Make sure that all valves are properly connected and working smoothly, and that they can be easily closed and opened.

- Make sure that the discharge and drain valves are working effectively.

- Inspection of electric or diesel engines

- If using a pump with an electric motor, the electrical system should be checked to ensure it is in good working order.

- If using a diesel engine, the fuel level should be checked and it should be ensured that the engine is running smoothly without problems.

- Alarm device testing

- Ensure that the alarms connected to the pump system are functioning correctly and issue an alarm in case of any system malfunction or when the pump is switched on.

- Recording results

- All observations, inspection results, and tests should be recorded in an official performance review report to ensure the system meets standards.

- routine maintenance

- It is recommended to perform a periodic inspection of UL FM approved fire pumps once a week for manual operation, and a comprehensive inspection once a month or every three months according to local requirements and international standards.

- Following these steps ensures that fire pumps are ready to operate in emergencies and effectively protect facilities.

Read more about: co2 fire suppression system

Fire pump testing

The annual flow test measures the flow and pressure of the fire pump, helping to detect any potential problems with pump performance or water supply. The test involves running the pump at various flow rates, up to 150% of its operating capacity, to ensure its efficiency and readiness for emergency use.

Fire pump control panel

The fire pump control panel is the "brain" that runs the pump system, as it is specifically designed to control and monitor the operation of diesel engines and jockey pumps.

The panel allows the pumps to be operated in both manual and automatic modes, and it also activates or deactivates pump drivers according to specific conditions to ensure an effective response in emergencies.

You can contact United Company The exclusive and sole agent for Watex UAE in Egypt, through phone numbers or our website, to obtain all information and prices of UL FM approved fire pumps.